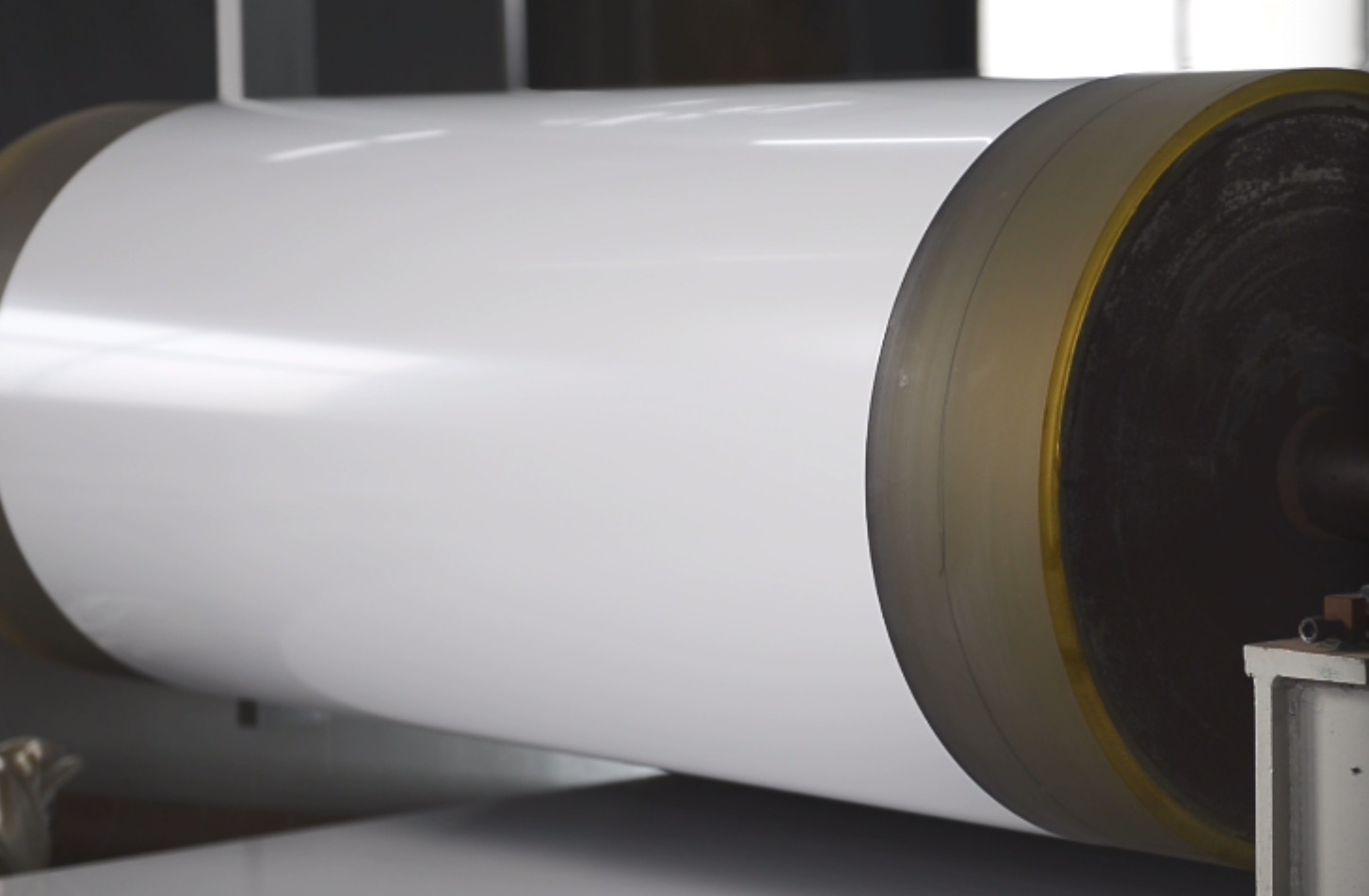

Alloy3105 0.022" x 12"inch White / White Color Flshing Roll Colored

Coating Aluminum Trim Coil For Aluminum Ribbed

Introduction:

This premium Aluminum Trim Coil is crafted from Alloy 3105,

renowned for its corrosion resistance, formability, and lightweight

durability. With a thickness of 0.022" (0.55mm) and width of 12"

(304.8mm), it is designed for precision applications in

architectural and industrial aluminum ribbed systems. The coil

features a dual White/White color scheme with a high-gloss flashing

roll finish, combining aesthetic appeal with functional

performance. The colored coating offers UV resistance,

weatherability, and scratch resistance, ensuring long-term color

retention and surface integrity. Ideal for roofing, siding,

decorative trims, and ribbed panels, this coil meets ASTM B209 and

AAMA 2605 standards for quality. It is supplied in precision-wound

rolls, protected with anti-scratch packaging for safe

transportation.

Parametar & Specification:

| Parameter | Specification |

|---|

| Product Name | Alloy 3105 Colored Coating Aluminum Trim Coil |

| Alloy Type | 3105 (Al-Mn) |

| Thickness | 0.022" (0.55mm) |

| Width | 12" (304.8mm) |

| Color | White/White (Dual-Tone Flashing Finish) |

| Coating Type | Polyester (PE) or Fluoropolymer (PVDF) |

| Surface Treatment | Pre-painted, High-Gloss Flashing |

| Mechanical Properties | Tensile Strength: ≥140 MPa; Elongation: ≥3% |

| Application | Aluminum ribbed panels, roofing, siding, trims |

| Standards | ASTM B209, AAMA 2605 (PVDF Coating Option) |

| Packaging | Wound on steel cores, wrapped in PE film + kraft paper |

Customization | Available in other widths/thicknesses upon request |

Advantages:

Alloy 3105 colored coating aluminum combines the inherent strengths

of Aluminum-Manganese (Al-Mn) alloy with advanced surface finishes,

offering versatile benefits for architectural, industrial, and

decorative applications:

Corrosion Resistance:

- Alloy 3105’s natural Al-Mn composition provides superior resistance

to atmospheric corrosion, ideal for outdoor use (e.g., roofing,

siding).

Formability & Durability:

- High ductility allows precise shaping for ribbed panels, trims, and

complex designs without cracking. Lightweight yet robust, reducing

structural load while maintaining rigidity.

Aesthetic Appeal:

- Vivid, uniform colored coatings (e.g., White/White dual-tone) with

high-gloss or matte finishes enhance visual appeal for modern

interiors/exteriors.

Durable Coatings:

- Polyester (PE) or fluoropolymer (PVDF/AAMA 2605) coatings offer:

- UV resistance: Prevent fading and degradation in harsh sunlight.

- Weatherability: Withstand rain, snow, and temperature extremes.

- Scratch resistance: Maintains surface integrity during installation

and use.

Low Maintenance:

- Pre-painted finishes eliminate post-installation painting, reducing

labor costs. Easy to clean and resistant to stains.

Thermal Efficiency:

- Aluminum’s natural thermal conductivity supports energy-efficient

designs in buildings.

Sustainability:

- 100% recyclable alloy reduces environmental impact. Long lifespan

minimizes replacement waste.

Versatility:

- Suitable for architectural (roofing, siding, fascia), industrial

(equipment casings), and decorative (interior trims, signage)

applications.

Standard Compliance:

- Meets ASTM B209 (aluminum sheet standards) and AAMA 2605 (premium

PVDF coating performance).

Cost-Effectiveness:

- Balances performance and affordability, offering long-term value

through durability and low maintenance.

Use Applications:

Ribbed panels, roofing systems, cladding, gutters, window trims,

interior decor, and industrial machinery components.

Ribbed Panels Industry Overview

The ribbed panels industry manufactures lightweight, structurally

reinforced panels for architectural, industrial, and transportation

applications. These panels feature corrugated or ridged designs

that enhance strength, rigidity, and load-bearing capacity while

reducing material usage. Key materials include aluminum (e.g.,

Alloy 3105), steel, and composites, chosen for corrosion

resistance, formability, and durability. Common applications:

roofing, siding, cladding, storage tanks, and equipment casings.

Advantages: cost-effective, easy installation, weatherproof, and

design versatility (custom colors, textures via pre-painted

coatings). Aluminum ribbed panels (e.g., 3105 alloy with PVDF/PE

coatings) dominate due to corrosion resistance, recyclability, and

thermal efficiency. The industry prioritizes sustainability, with

recycled materials and long lifespans. Innovations focus on smart

coatings (self-cleaning, UV-resistant) and modular designs for

rapid assembly. Market drivers: urbanization, infrastructure

growth, and demand for energy-efficient buildings.