Changzhou Dingang Metal Materials Co., Ltd. / Jiangsu Senruida New

Materials Co., Ltd. is comprehensive enterprise integrating in

production, processing, and sales. Situated in Changzhou City and

Huai'an City, Jiangsu Province, we specialize in manufacturing

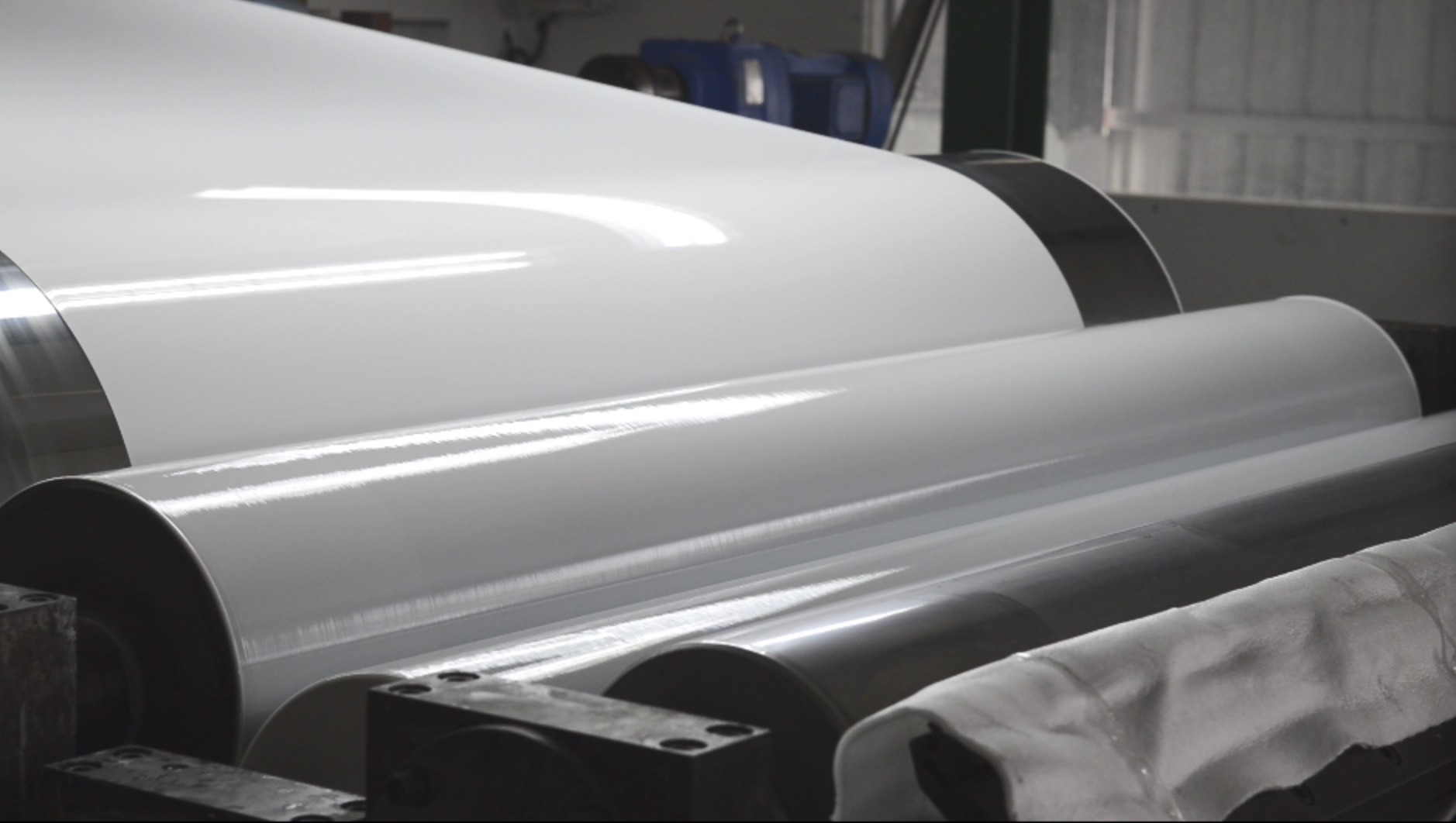

color coated aluminum coils, film-coated aluminum coils, and

providing aluminum coil surface coating processing services. Our

facilities boast 6 coating and plating production lines, along with

6 high-precision horizontal and vertical cutting equipment,

enabling us to produce a diverse range of products ranging from

ultra-thin to ultra-thick (0.08-6.0mm) and ultra-narrow to

ultra-wide (10-2670mm) series.

Our products find extensive applications across various industries

including construction, decoration, household appliances, kitchen

and bathroom, food packaging, gardening, lighting, automotive,

advertising, transportation, and more. With over 20 years of

experience in production and development, we have established a

global presence, exporting our products to more than 50 countries

and regions worldwide, including Japan, the United States, Canada,

South Korea, the Netherlands, Mexico, Brazil, Chile, India,

Indonesia, Vietnam, and the Philippines.

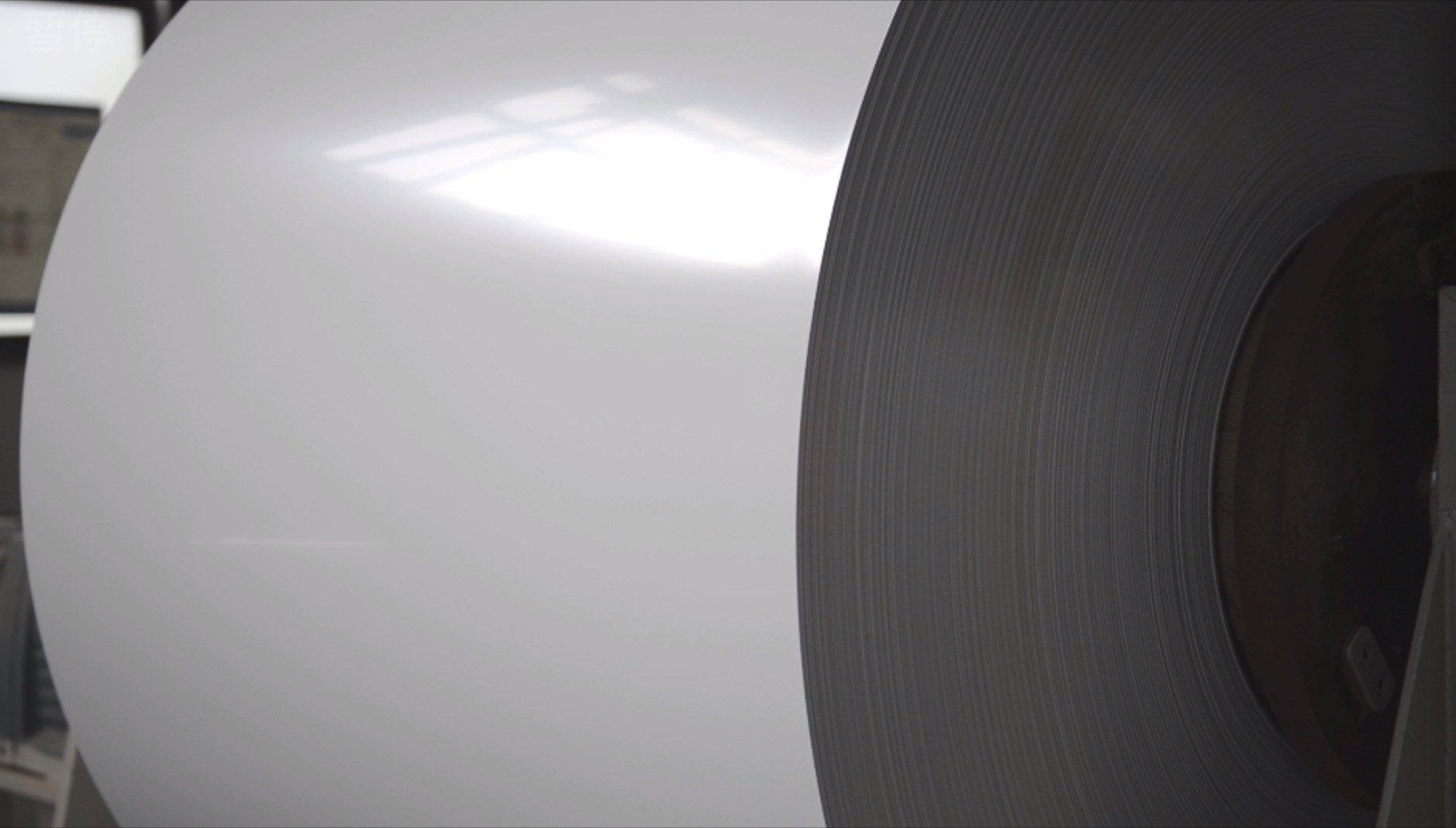

Our product range encompasses a comprehensive selection of

coatings, including high gloss, matte, monochrome, multi-color,

brushed, wood grain, and marble finishes. We also offer embossed

patterns such as diamond, orange peel, wood grain, and irregular

textures, achieved through advanced extrusion processing

techniques. From container and carriage ultra-wide color-coated

coils to roof aluminum-magnesium-manganese alloy series, our

products cater to diverse application scenarios.

Currently, our company has over 800 employees, with research and

development personnel accounting for over 15% of the workforce.

Committed to the principle of building a century-old enterprise in

China, we are dedicated to providing top-quality products and

services to our customers. We warmly welcome you to visit our

company and guide our work, as we strive to create a bright and

mutually beneficial future together.